Petroleum Oils and Waxes

Colour is an important indicator of type and quality of oils. In some cases, colour is used to mark and recognise fuels. Others, such as food quality waxes, need to be colourless. Lovibond® have spent decades helping the industry to measure colour consistently.

We can help you communicate and control colour throughout your process.

If you'd like to see for yourself, just ask us for a demonstration.

Using a Lovibond® colour measurement system means that you can communicate and control colour quality consistently throughout your supply chain.

If you would like some help with a colour matching issue right now, send us a sample of your product or ingredient and we can help you to decide the best method of measurement and colour scale to use. We can also provide some advice on colour tolerances. Just click below and tell us what you need.

Visual or automatic? Standard Illuminant D65 or D50? Two degree or ten degree standard observer?, CIE L*a*b* or CIE L*c*h*? Metamerism? Often what we want to know is simple simply “how can I ensure my colour matches consistently?” So we have put together some free short courses to help you to navigate the path to simple colour management and control. If you would like to take a course just click below and create a free account in our Learning Portal (you can use your social media account if you like), your courses will be available immediately.

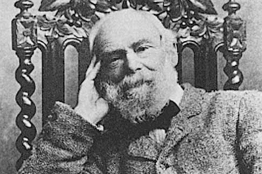

Lovibond® has its origins in the brewing industry and we have been measuring colour since 1880. Joseph Lovibond was the first person in the world to develop a practical colorimeter to ensure the high quality of his beer. He was the originator of the Lovibond® scale. We still use the scale as our company logo today. Still a family owned business but now global, at Lovibond® we value our heritage.